£0.00

0Dray Pads | Cellar Pads | Drop Bags

BIL Dray Equipment offers superior product quality and excellent value.

BIL have successfully supplied the brewing industry for many years. To continue to do this consistently, we need to make sure the equipment we supply is of the highest standard, but also with that little something different to separate us from the rest.

Here we will take a look at our range of dray and cellar pads explaining their application and the benefits of choosing the right type of dray pad and how this can help your business in the long term.

Dray pads

Dray pads often referred to within the industry as vita pads or vita beds are used specifically for the unloading of casks and kegs from a vehicle to the ground. They are also used in cellar drops.

The main use of a dray pad is to absorb the kinetic force between the keg and the ground. This is a repetitive action so a high quality dray pad increases the longevity of the kegs / barrels and also helps reduce noise.

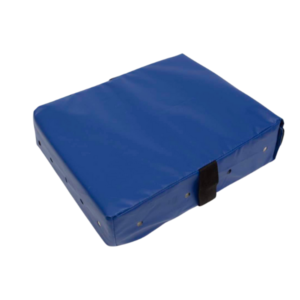

The dray pads supplied by BIL are manufactured with multi layered foam and insertion rubber. They also come with a tough plastic cover that fastens with Velcro to ease replacement. The pads are tiered with a three-layer construction, the outer layers are manufactured from softer energy absorbing foam with the central layer featuring a harder ‘recon’ foam to resist impact. This unique design makes the pads much easier to use and last much longer when used on a regular basis.

The dray pads are offered in one main size of 600mm x 600mm x 300mm which is standard across the industry.

De-Stacking pads

De-Stacking pads are manufactured in an identical way to the dray pads with the same unique properties including softer energy absorbing outer layers and a harder recon centre.

De-stacking pads are not as large or as deep as dray pads at 500mm x 400mm x 125mm. They are often used for smaller product where the distance of the drop isn’t as great as into a cellar, this means there isn’t the need for them to be as dense as other pads. They are mainly intended for the topping of casks and kegs in the warehouse or on the vehicle bed.

De-stacker pads are often used for lower impact applications mainly within a warehouse environment.

Cellar pads

Cellar pads are designed to be larger and assist the fall of containers that are dropped vertically into the cellar. As standard our cellar pads are 900mm x 900mm x300mm.

The cellar pads are generally placed at the base of the drop and contained within three walls. Being larger there is more room for product and this helps with the distance product is lowered or dropped from as there is a larger surface area.

Our cellar pads conform to the BLRA/HSE approved code of practice from manual handling and as with Dray and De-stacker pads are manufactured from both softer and recon foam.

Cellar pads are manufactured from multi-layered foam and insertion rubber for high durability with the maximum keg size recommended at 36 gallons.

Cork bags

Commonly known as blobbies, pigs, cork dumpers and drop bags our cork bags are filled with whole corks and can absorb the force of falling containers.

The bags are double skinned with the outer cover being manufactured from a woven recycled plastic material.

Often with cork bags, industry professionals will break the internal cork up to soften the cork bag for a more cushioned drop.

Cork bags are most commonly used in breweries and is a more traditional way of absorbing impact, however it is still a very popular method to this day due to its cost effectiveness.

Why choose BIL pads?

As one of the industries leading manufacturers of manual handling equipment BIL have a wealth of knowledge and expertise in this area.

Each pad type has been designed and refined uniquely for its application with a common theme being the internal design of the foam which provides the best protection and ensures a longer life for both the pad and the products being handled.

Why choose one over the other?

Each pad type has its own individual use whether you are using it for larger drops i.e. the cellar pad, low impact drops in the warehouse using a de-stacker pad or regular cost effective use which would be the cork bag! Each pad effectively does a similar job but choosing the right pad will be important to your everyday processes to ensure your business remains efficient and effective.

It may be recommended to use different pad types across differing areas of your business whether this be in the warehouse or out on deliveries.

It is not only pads we supply into the industry. Take a look at our trucks, ropes, carbine hooks and other dray and brewery equipment, all designed to the highest standards and ready to maintain safe handling, save, costs and increase productivity – all of which contributes to the profit line.

At BIL our team are always happy to help with enquiries and we take pride in working with our customers and partners to provide effective manual handling solutions, be it for the brewery industry or any other industries. Just email us at sales@bilgroup.co.uk or call us directly on 01249 822 222 – we are ready to help.